Omeg Manufacturing & Engineering Services

Omeg Ltd offer a range of complimentary Manufacturing & Engineering Services in addition to Potentiometers including;

- Plastic (Injection) Moulding,

- Metal Component Stamping,

- Tool repair, maintenance & modification and machining of hard materials.

- Laser Marking/Engraving items for product identification and other purposes.

We welcome enquiries from anyone interested in these services and will provide a competitive quotation based our your requirements whether they are large volume or small batches.

Details of our equipment and the services available are shown below

To make an enquiry about the range of services we can provide, please contact our sales department with an outline of the service that is of interest to you.

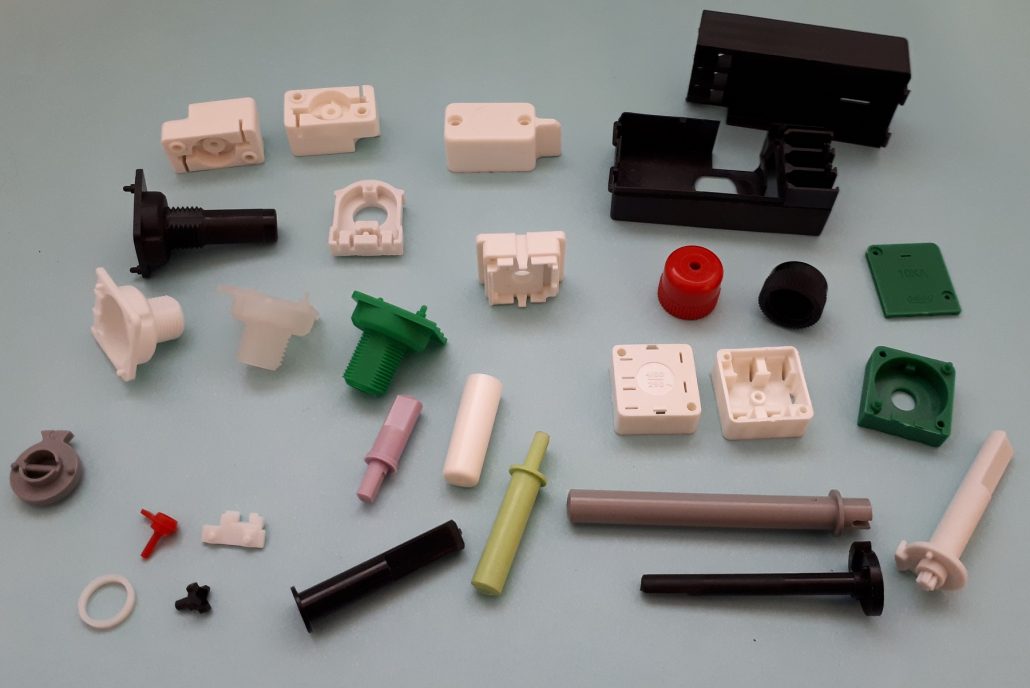

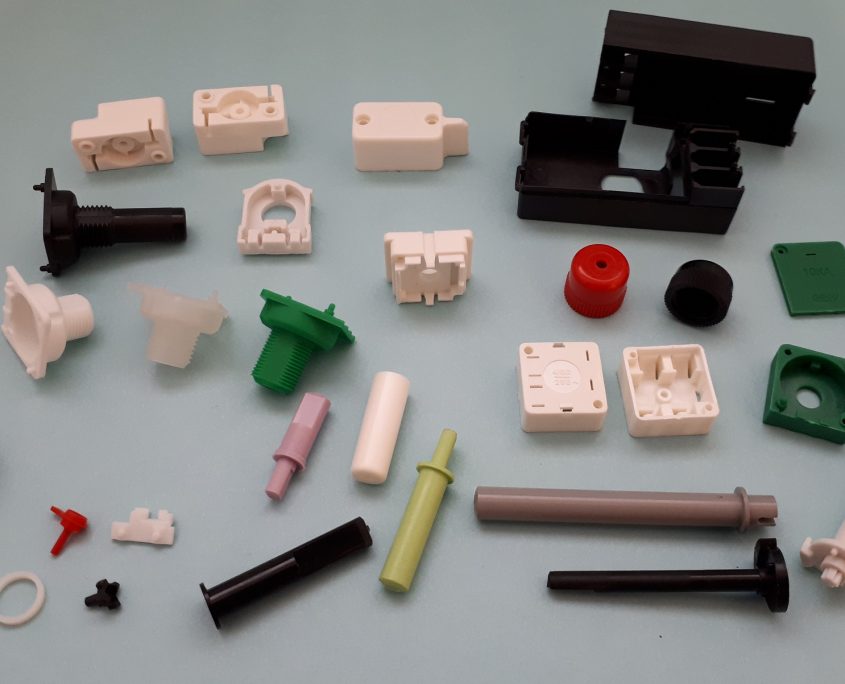

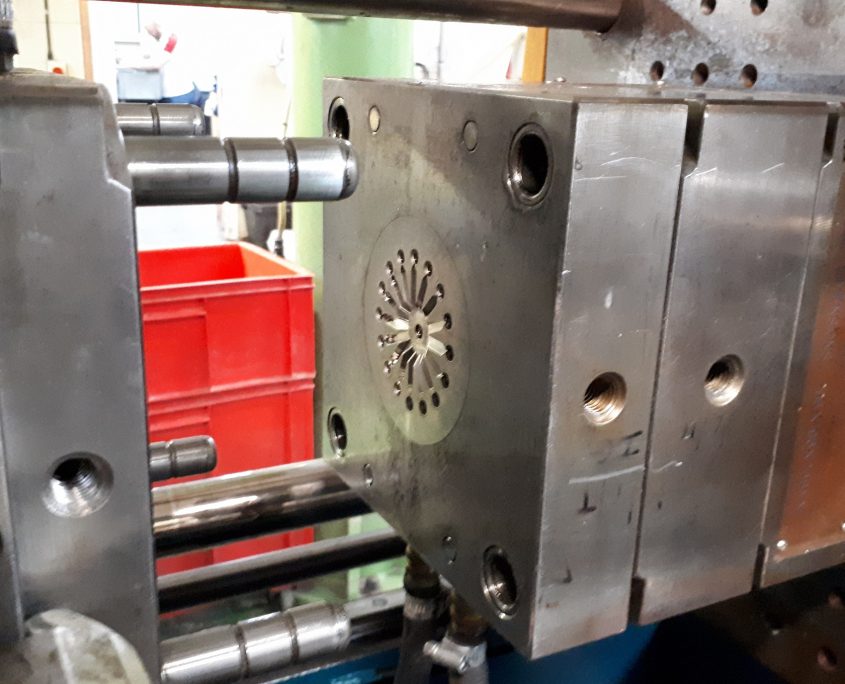

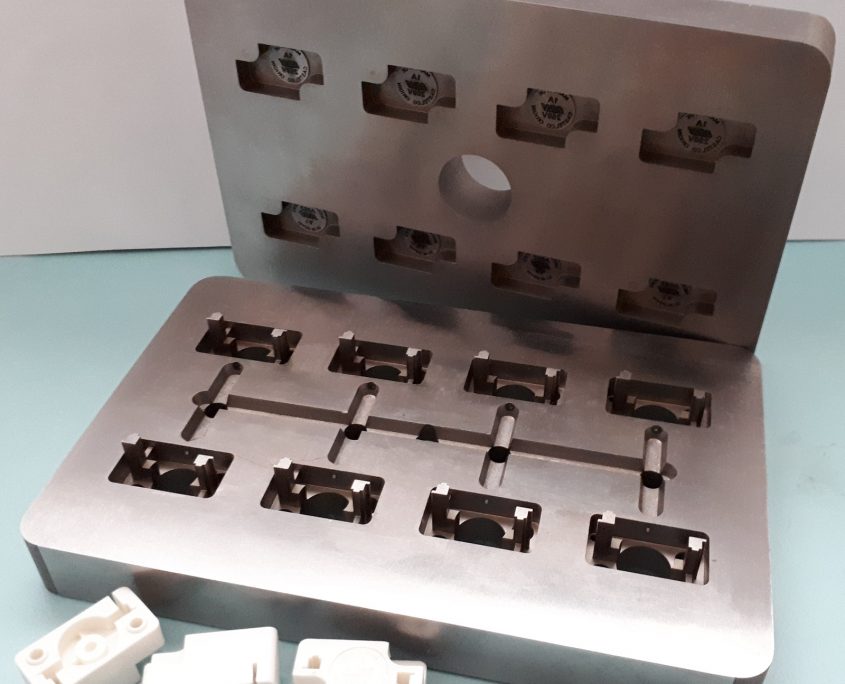

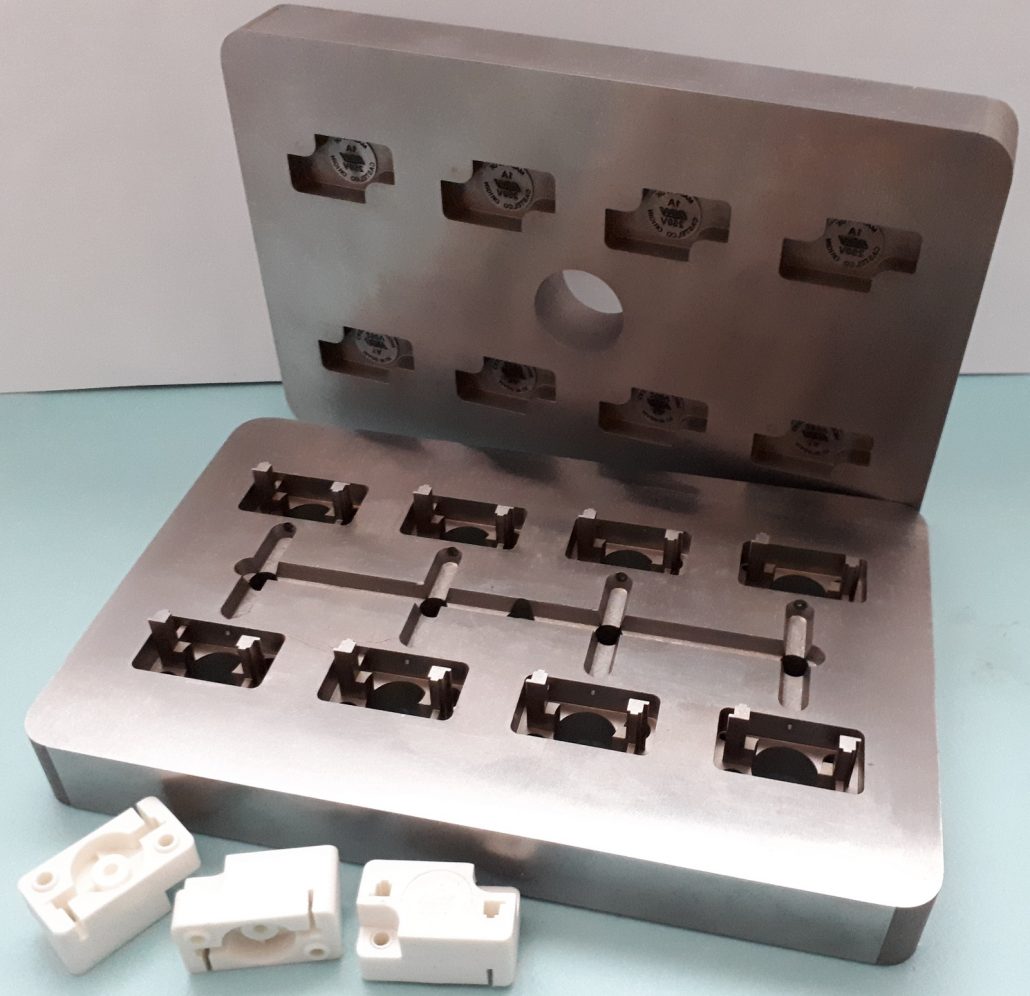

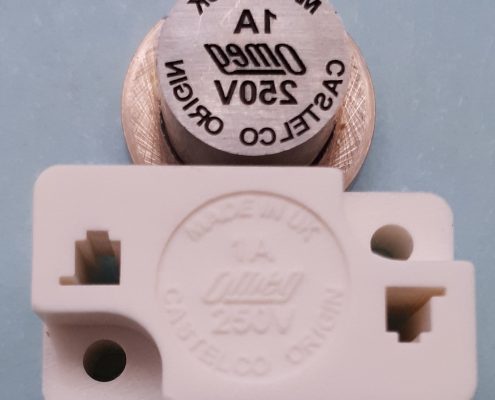

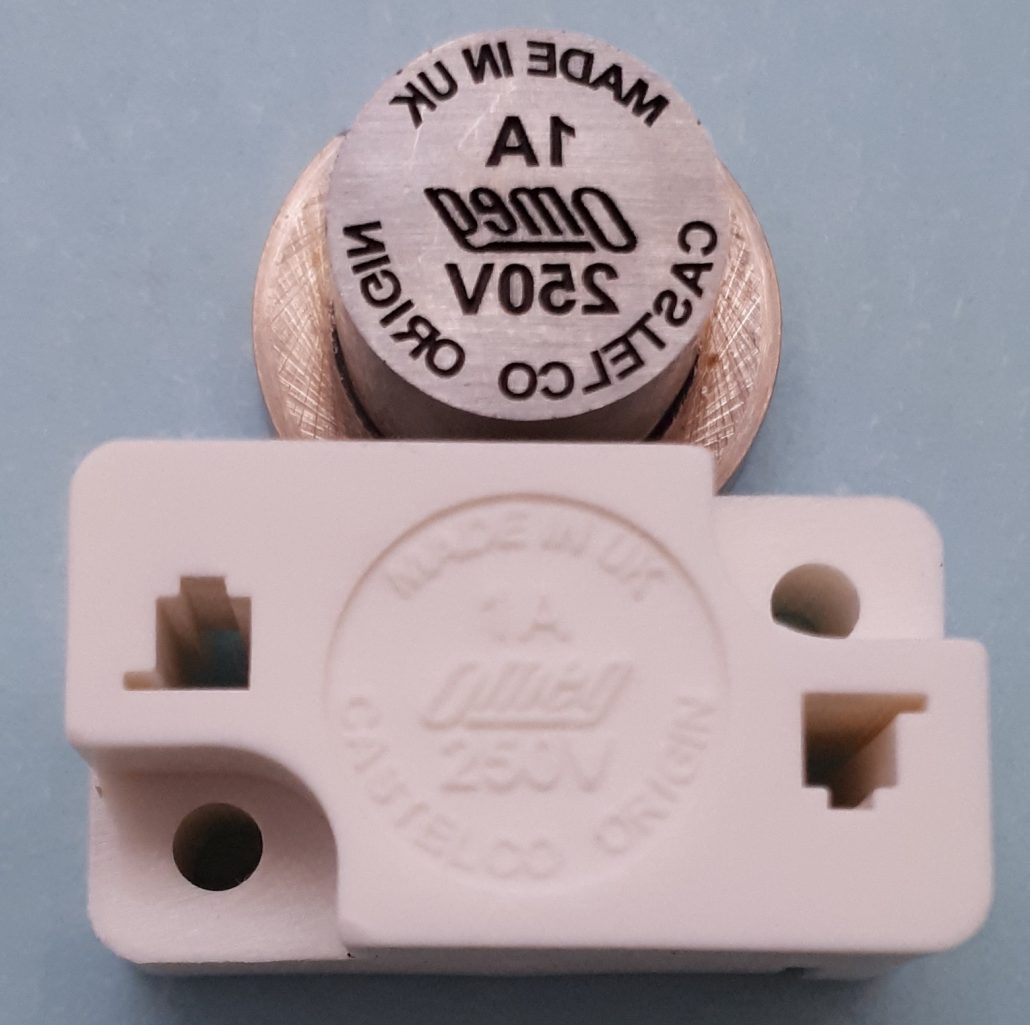

Injection Moulding

The injection moulding department produces moulded plastic components using 6 BOY 30M moulding machines. These have a 30 tonne capacity and are ideal for producing small plastic parts and components from multiple impression moulds.

Minimum mould shut height 200mm, Maximum mould height 340mm

Parts can be produced using a wide range of materials including:

- Glass Filled Nylon (Beaded or Stranded)

- ABS

- PBT (Polyester)

- Polycarbonate

The Moulding department is supported by an in house Tool Room which provides maintenance, modification and repair of the customers moulds and tooling.

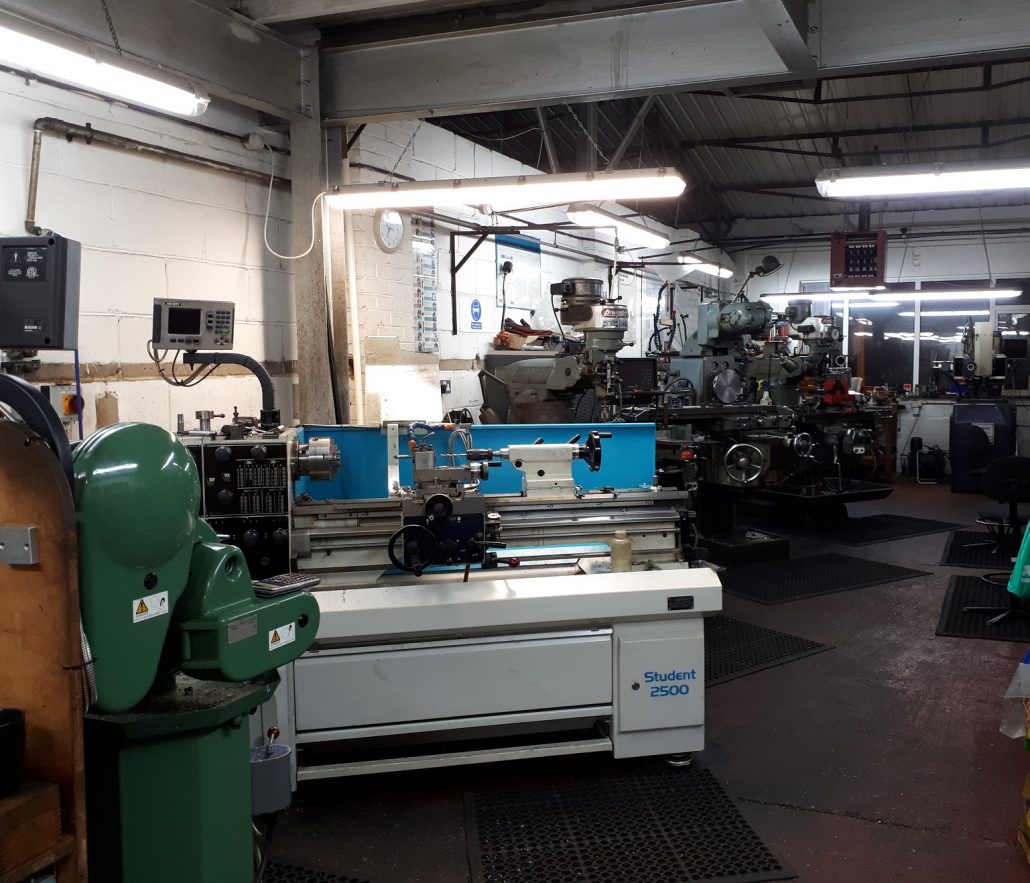

Tool Room and Engineering

Omeg Ltd has a well equipped Engineering department and experienced ‘time served’ Toolmakers

Services offered:

- Mould & Press Tool Repairs and Modifications

- Electrical Discharge Machining (EDM) of Hard Metals such as Polycrystalline Diamond and Tungsten Carbide

- ‘Fast Hole’ EDM drilling in Hard, Soft and difficult to machine materials

- EDM of complex shapes and parts to very close tolerances

Plant List:

- GF CUT 20P Wire Eroder EDM (350 X 250 X 250 capacity, 0.25 and 0.15 Ø wire)

- GF FORM 20 Die Sinker EDM (350 X 250 X 250 capacity)

- GF DRILL 20 Fast Hole Driller EDM (300 X 250 X 300 capacity)

- EUROSPARK H245 Die Sink EDM

- 2X BRIDGEPORT Milling Machines

- DUFOUR Universal Milling Machine

- NEWALL JIG BORER

- 2X J+S Surface Grinders

- MYFORD Cylindrical Grinder

- CLARKSON Tool & Cutter Grinder

- COLCHESTER 2500 Long Bed Centre Lathe

- MYFORD Sigma 7 Lathe

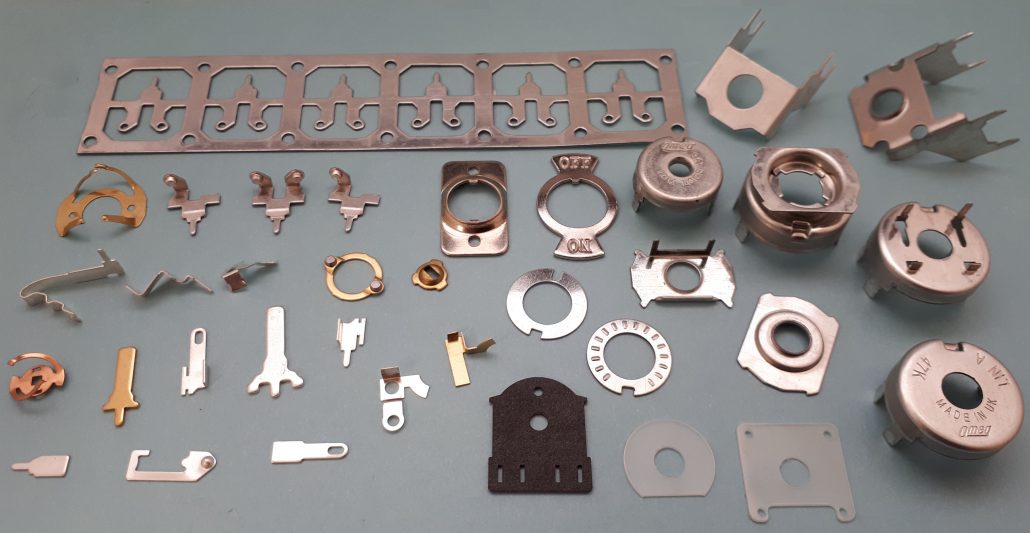

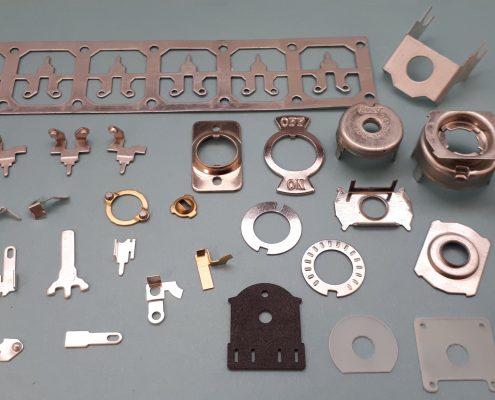

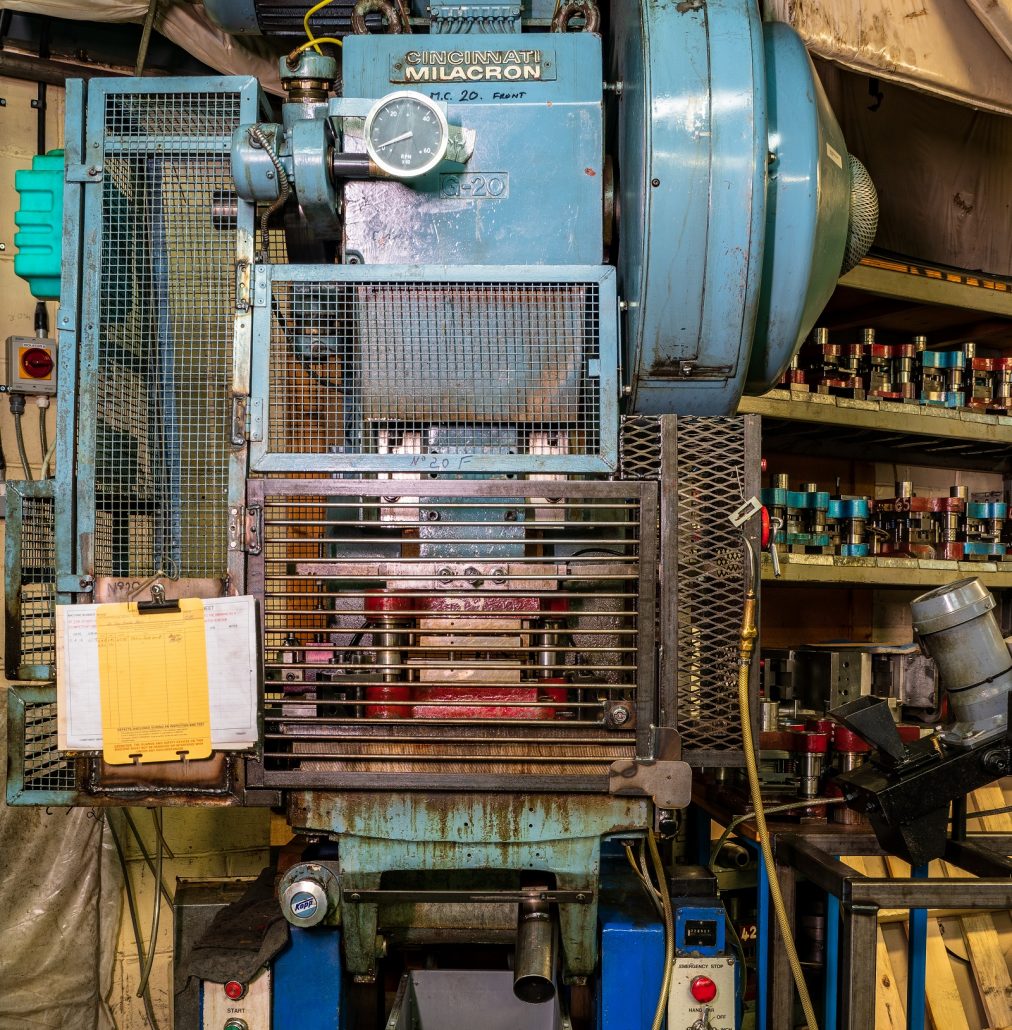

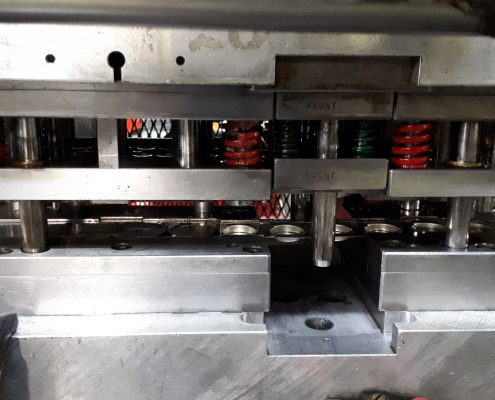

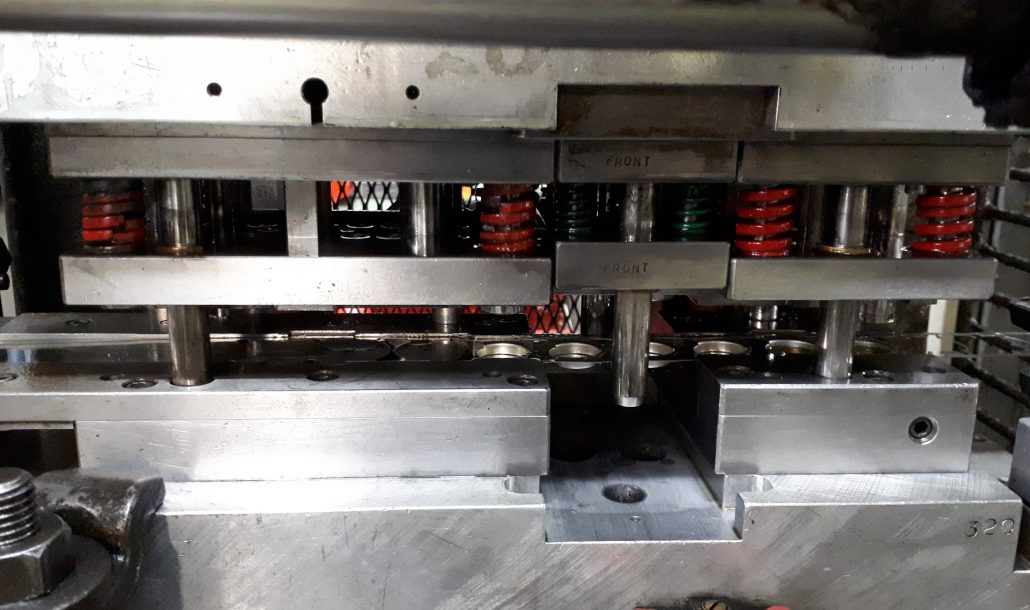

Metal stampings/pressings

The Press Shop produces stamped/pressed metal components using a range of Stamping Presses. These have a 20 or 30 tonne capacity and are used to produce small metal parts and components from strip materials

Parts can be produced using a wide range of materials including:

- Tinplated Steel

- Brass

- Copper

- Phosphor Bronze

- SRBP

- Rigid (punchable) Plastic

The Press shop is supported by an in house Tool Room which provides maintenance, repair or modification of the customers tooling.

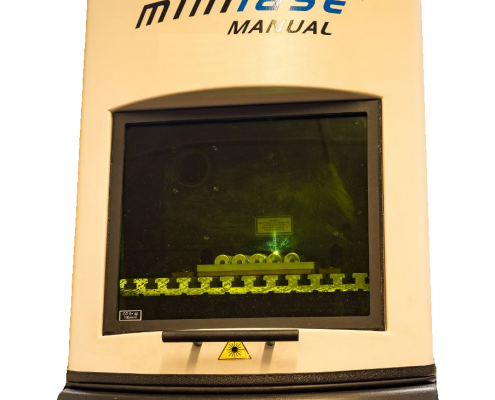

Laser Marking and Engraving

The laser marking system allows Omeg Ltd to label items with a permanent engraving.

The Fibre Optic Laser allows marking or engraving on almost any surface and material without the need for pre-treatment. Metals can be marked or engraved to varying depth or with a simple anneal mark. Plastics of various grades and colour can be marked by producing a colour contrast between the original base material and the marking.

Customer specific markings such as Part Numbers, Date Codes, Bar Codes or QR Codes can be engraved for identification purposes.

Artwork such as Company Logo’s, Names and Symbols can be added using Vector or Bitmap files provided by the customer.

The Engraving system can also be used to make stamps, punches and mould inserts from hardened materials

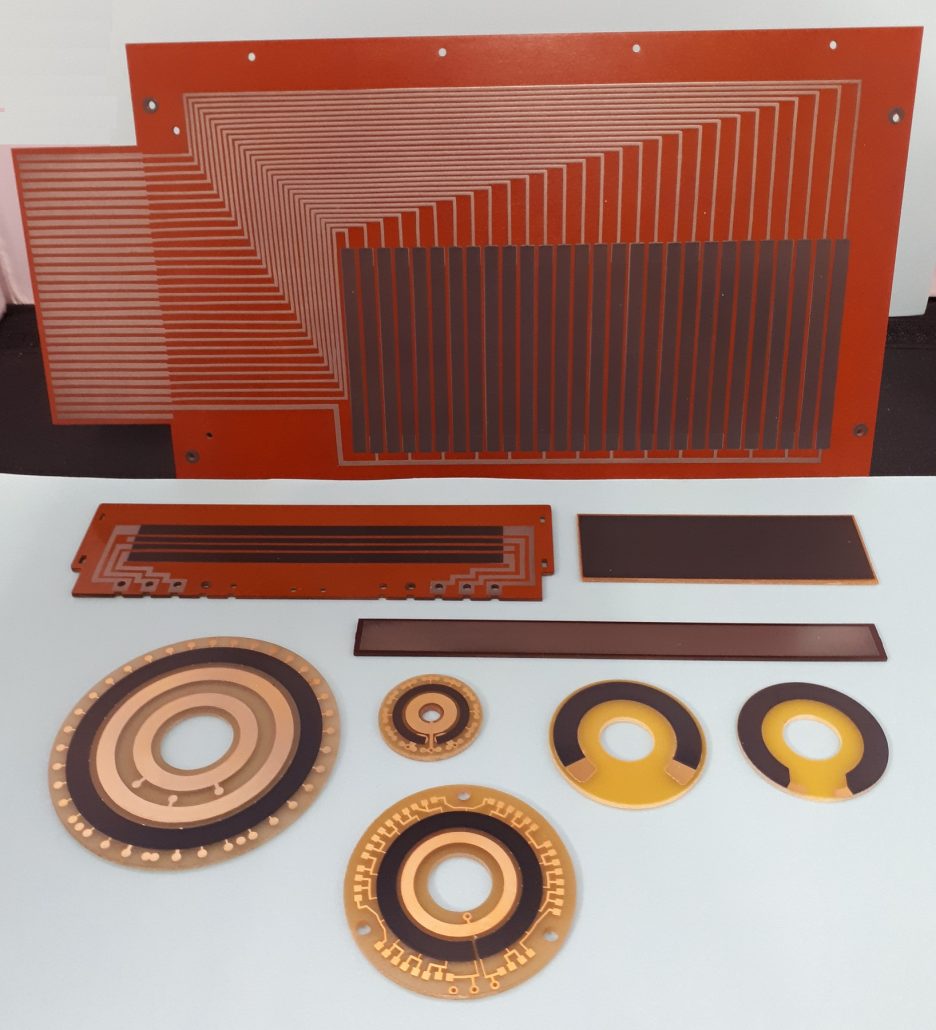

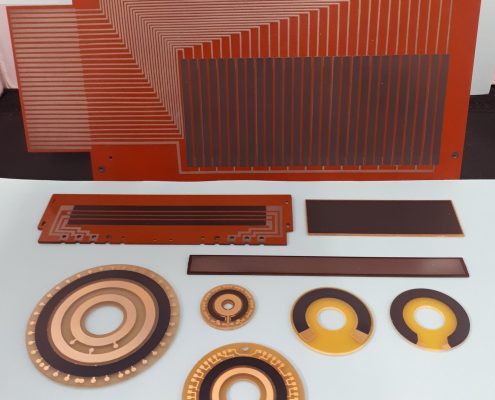

Printed Resistors

Omeg Ltd can supply printed resistors for customers to assemble into their own devices.

These are produced using our Conductive Polymer inks and can be printed onto FR4 PCB material with etched copper terminations or SRBP

If long life is required the resistor can be ‘Flush Bonded’ to the substrate